Automation & Controls Division

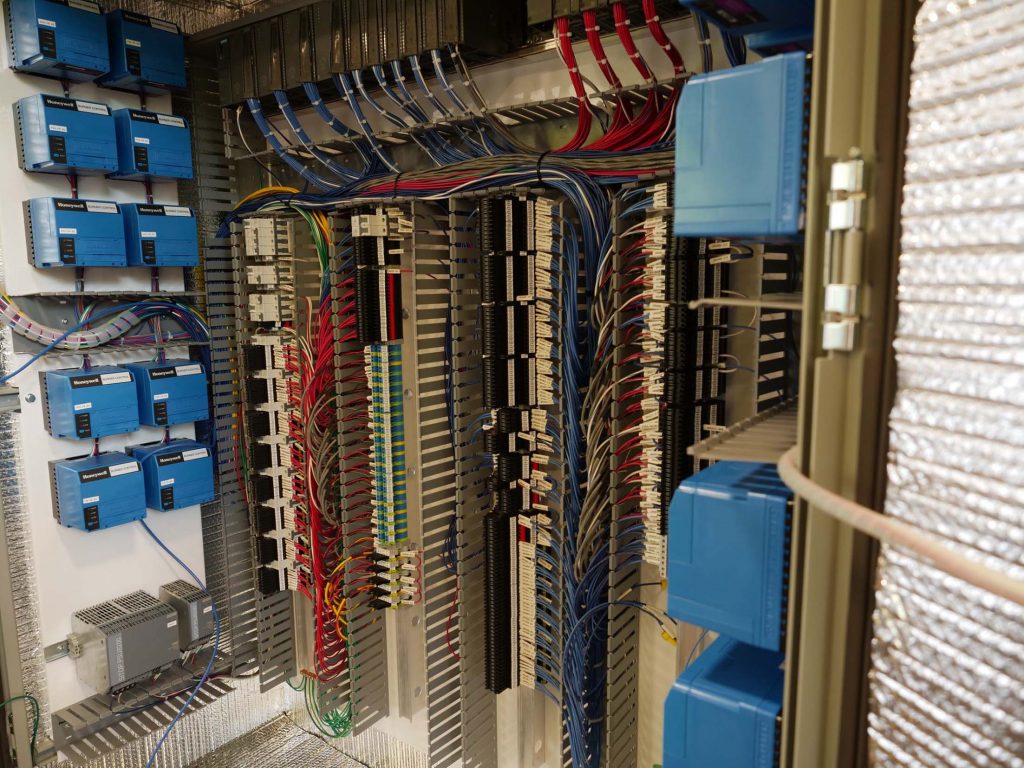

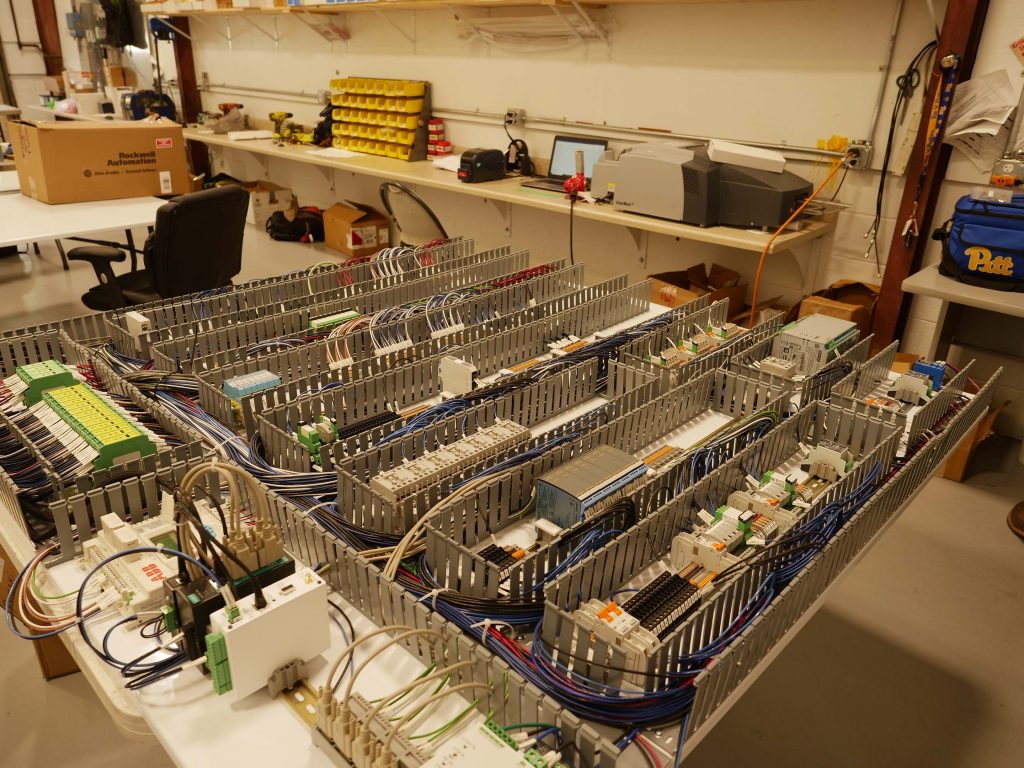

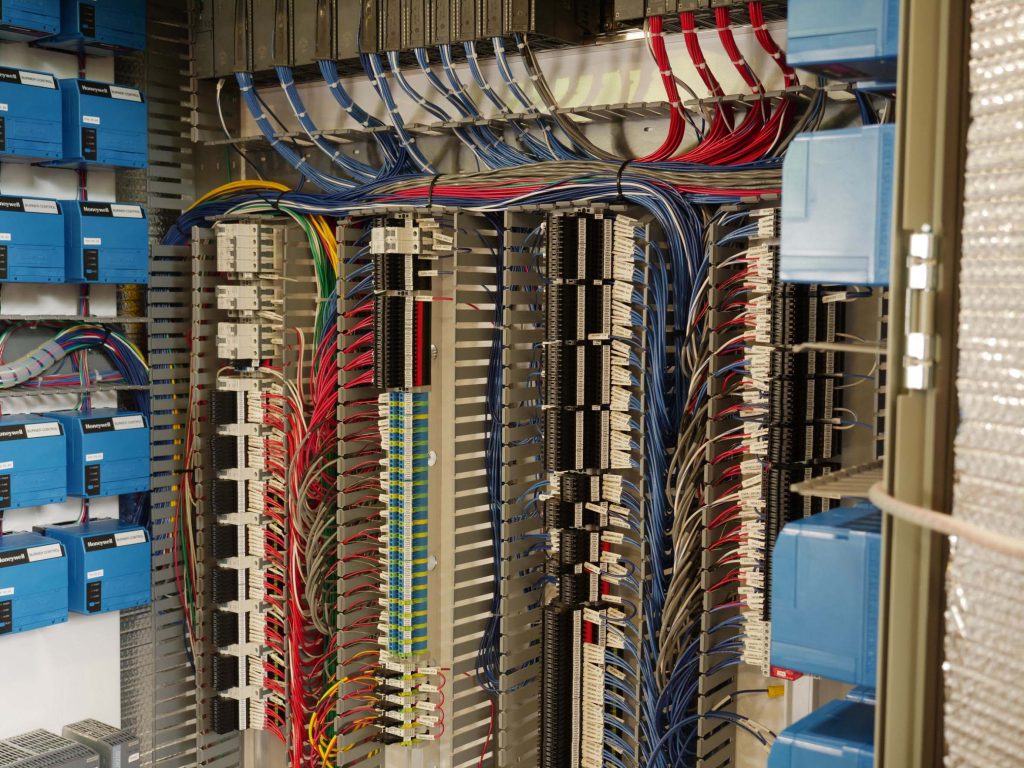

One of Hartman and Hartman’s most valuable assets is our UL508A certified control panel fabrication shop. Our commitment to building quality control panels for industrial and oil and gas applications led our Automation leadership to pursue and achieve the UL508A certification to better serve our customers. To meet Underwriter Laboratories (UL) standards, our technicians trained under a UL engineer to earn certification status, including four annual inspections to ensure compliance.

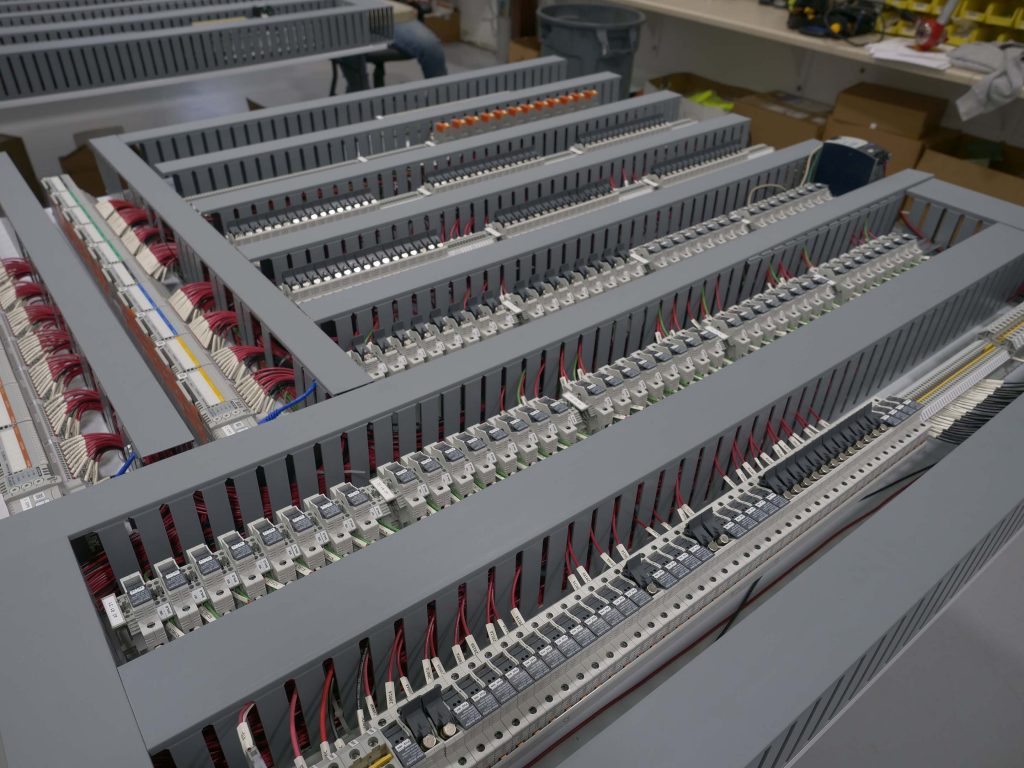

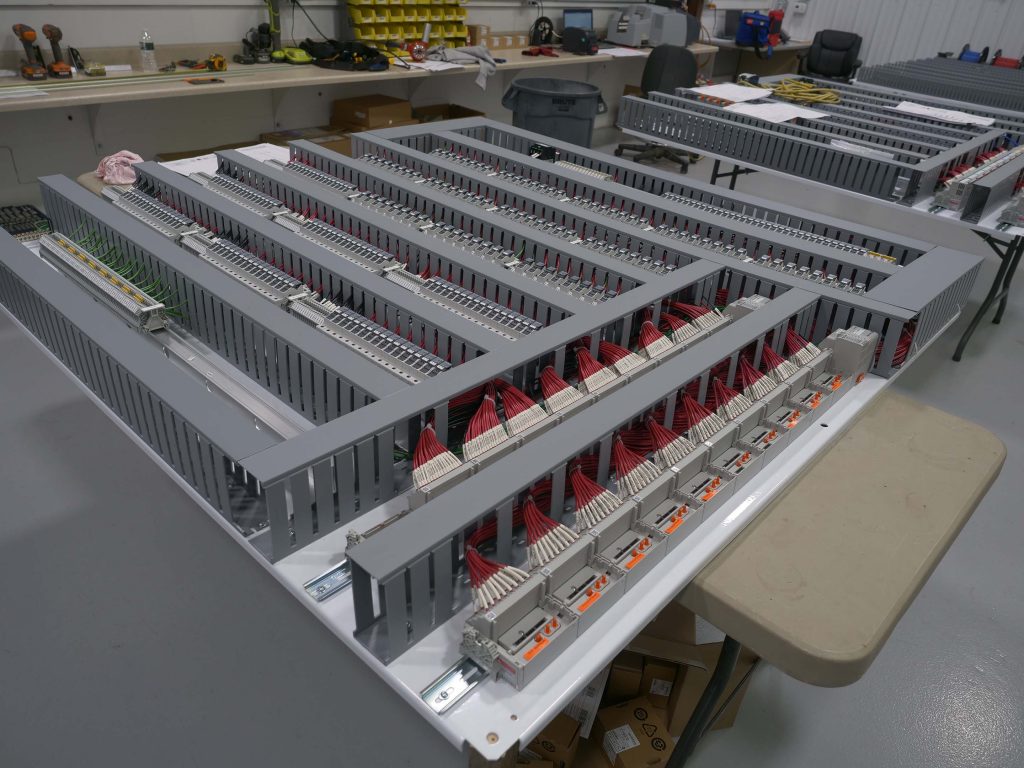

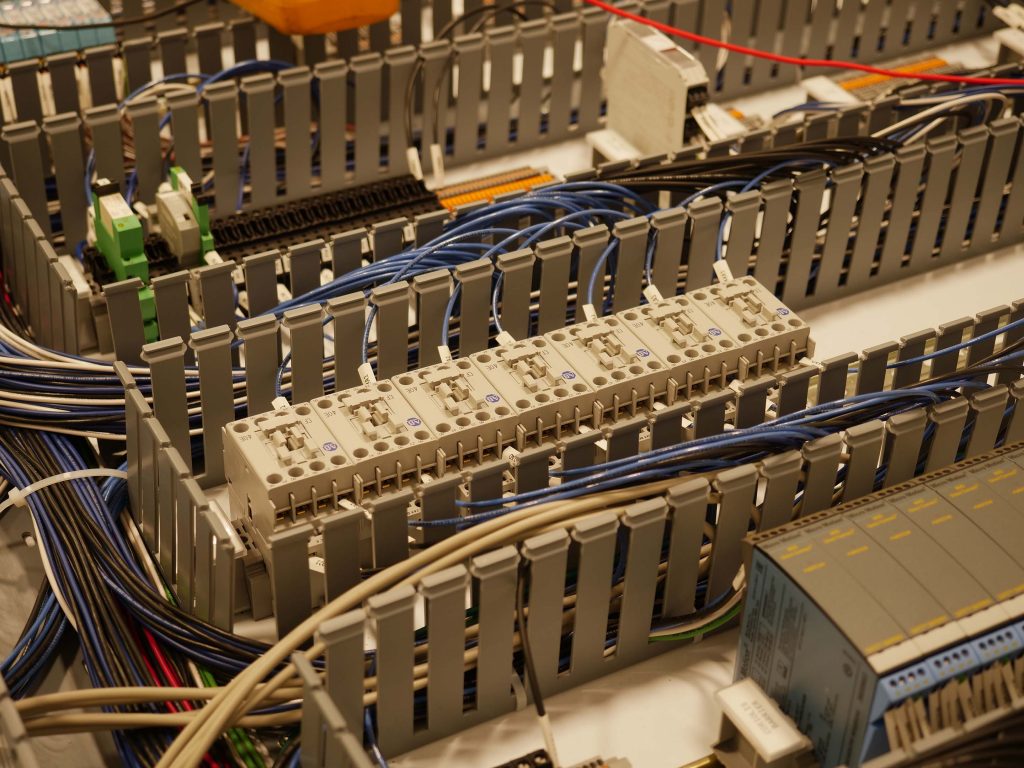

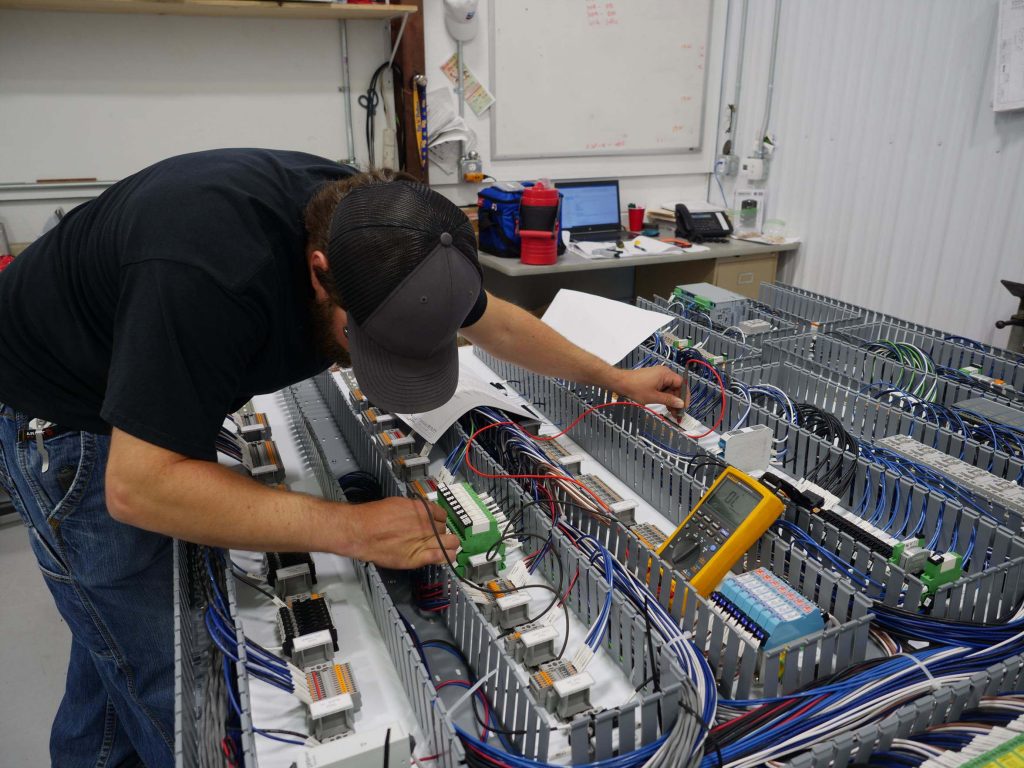

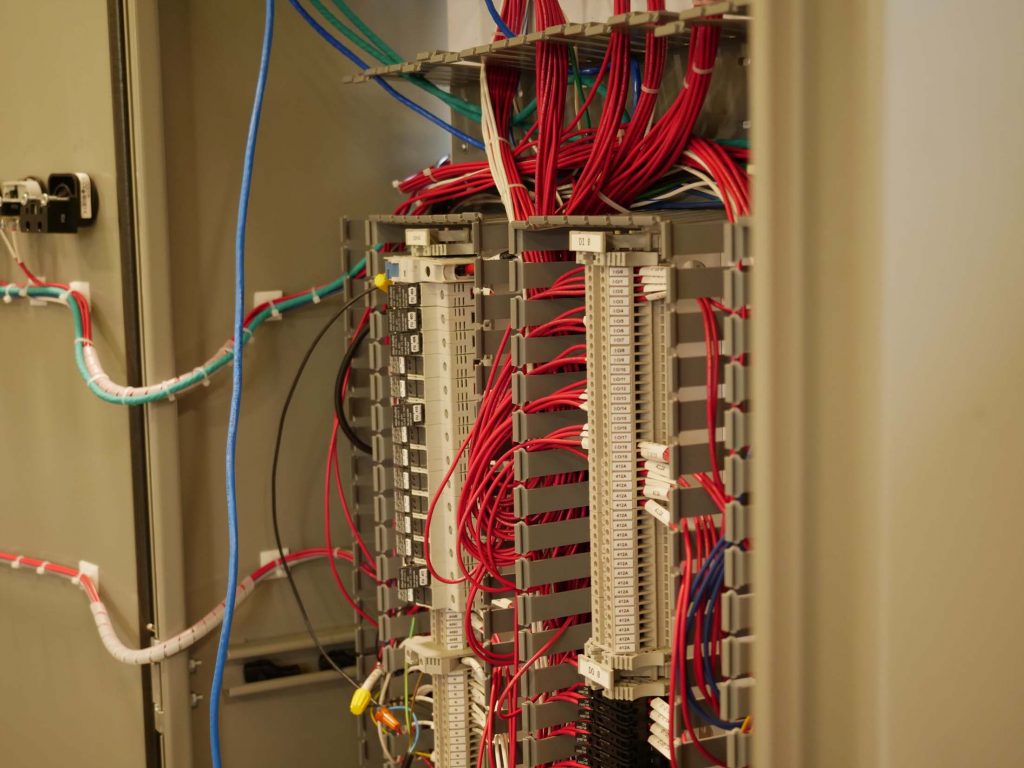

Our panel shop technicians are equipped to build control panels per customer drawings and specifications as well as work with our Automation team to design custom solution to meet the ever-changing needs of manufacturing, industrial, and oil and gas clients. Hartman’s Automation team ensures delivery of quality control panel products that function as designed with a fit and finished appearance. Whether your control panel needs to be UL580A certified or not, you can be rest assured that all control panels are built to the same high standards. After the control panel is fabricated, it goes through a quality check to ensure it is built to the drawings.

Our panel shop has in house marking systems used for wire and terminal block markers which ensures everything in the panel is easy to read. We also work with a local engraving company to provide custom engraved nametags.

Why choose Hartman and Hartman Inc. as your UL508A certified panel shop?

- UL panels must be built by a UL approved panel shop.

- Panels are built to the highest quality.

- UL certified panels are required by some industries.

- UL certified panels are easier to get approved by third party inspectors.

- We can help customers to determine if their panel meets UL508A standards.

- Once a panel is UL508A certified, we can mass produce subsequent panels without having each panel inspected by UL.

When it comes to automation and controls construction, our skilled tradesmen handle every aspect of your project. From the design process, to development, to in-house staging we have you covered. No detail is too large or too small.

We’re experts in electric control panel fabrication so you can be assured you will have all the proper instrumentation and control panels needed to handle your facilities electrical needs.

Technicians and processes must change to keep up with innovation and increased complexity. That’s why we’ve grown to offer software design, programming, and device setup. This creates true in-house staging for our clients.

DESIGN

Detailed design, specification, and drafting:

- Instrumentation

- Control platforms

- Control panels

- Facility electrical

DEVELOPMENT

Software design, programming, and device setup:

- PLC Programming

- HMI graphic design

- RTU configuration

IN-HOUSE STAGING

Equipment assembly, setup, and testing:

- Instrumentation preassembly

- Machine testing

- Panel point-to-point

- Multiple panel system staging

- Factory acceptance testing

ONSITE COMMISSIONING

Field startup services:

- Instrument setup and calibration

- VFD and motor control setup

- Point checkout

- Network testing

- Function testing

- Startup assistance

ONSITE INSTALL SERVICES

Field installation services:

- Instrumentation and tubing

- Termination

- Networking

EXPERTISE

Experience in the following control and facilities:

- Process control

- Machine control

- Motion control

- Motor control

- Chemicals

- Manufacturing

- Metals

- Oil and gas

- Water and wastewater